How and where GRABO's are designed and made

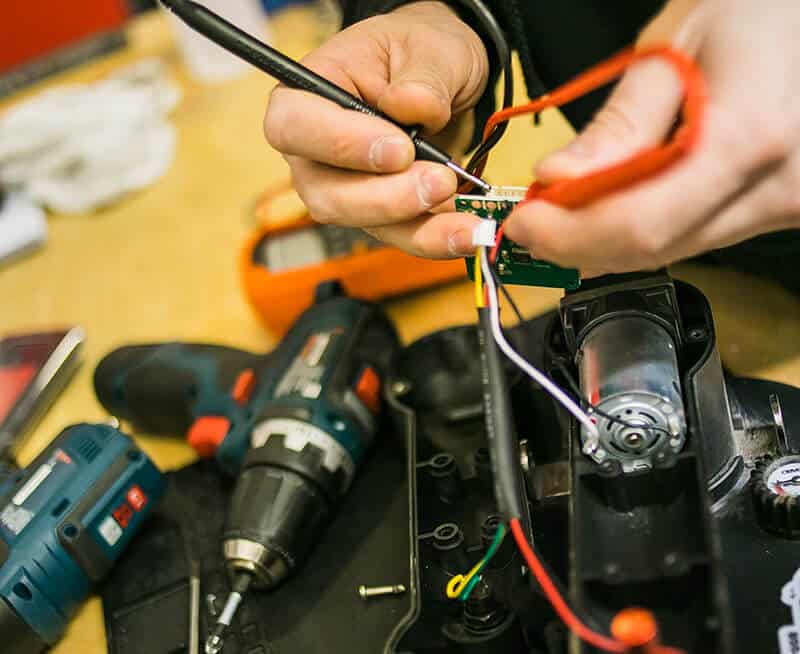

For us, GRABO products are way more than a power tool. We see them as a companion making heavy-lifting jobs fun and joy. With such profound vision, we can’t rely on others to manufacture our products. Therefore, we proudly design and produce every GRABO product at our wholly owned manufacturing facility.

Our vision, mission, and experience make us confident with our production facility, rather than utilizing 3rdparty OEMs. The assembly line is run by highly trained and professional staff on our payroll. These trained professionals produce all GRABO units and many of the parts and components. Every single unit goes through a quality assurance procedure and receives a unique serial number which is laser engraved on the unit after it passes all QC tests.

Our unique process flow is at par with large-scale manufacturing processes of hi-end products, like cellphones, cars, and cameras of top brands.

With complete control over the facility we do not only ensure quality products but also make it imperative that these products are competitively priced.

At factories, we produce power tools – At stores we sellpartners.

Here’s a breakdown of facilities owned and operated by Nemo Power Tools, the brand owners of GRABO.

- Company Headquarters — Hong Kong

- Wholly owned factory dedicated to GRABO — Huizhou

- Industrial engineering, logistics support and light manufacturing — Shenzhen

- R & D and engineering office — Israel

- Customer support, warranty centre, 2nd phase QC and sales — Las Vegas Nevada

Become a GRABO Insider

Get access to priority updates and other exciting bonuses now.