Do you want to increase your workplace productivity significantly? Ever thought about the idea of using tube lifting systems and what it would be will? Tube lifting systems have been widely employed for use in different industries and various purposes.

In this article, you will see the main reasons why you should adopt this fantastic technology.

Easy to Operate:

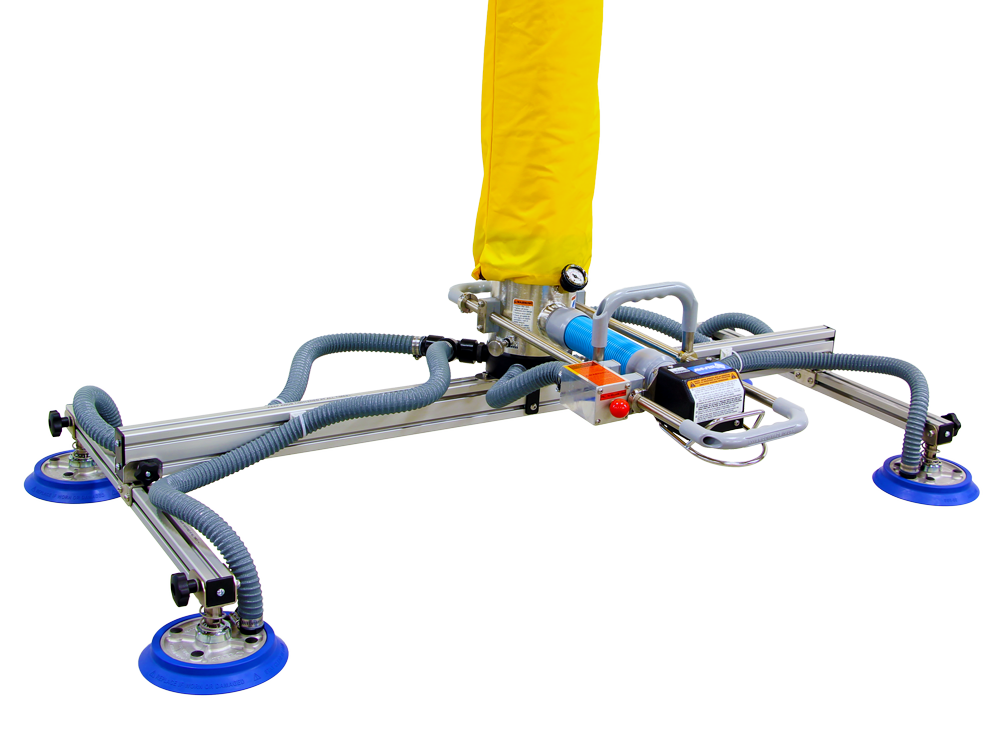

You don't need to undergo any rigorous training with tube lifting systems before using and operating the device. The system will firmly grab hold of the item you want to lift by utilizing vacuum suction to support and lift the load. This is all done in response to the control from the operator. There are also vacuum pads on these systems, which are for attachment of the device to the object that is to be lifted.

Ergonomic Handling:

Do you always have to deal with repetitive and continuous lifting operations? Whether it is a porous, semi-porous, or non-porous load you want to lift, you can be sure that you will achieve this with the tube lifters' help. There are different models available, and each of them has different specifications and requirements. Therefore, you need to be sure that the weight you are lifting and other factors are ideal for the lifting system you are using.

Quality Design:

There are different types of materials used in the manufacture of lifting systems.

Tube lifters are rapidly becoming the choice, especially when a single operator handling is most desired. It can also be suitable for the repetitive process and moving of heavy loads. What's more, is that they are affordable and readily available.

You can use these devices to pack small appliances, furniture, TVs, computer equipment, or any other item you can think of, provided that the items can be attached to the vacuum pads. There's no limit to the lifting operation that can be performed with this device. You can also lift cartons, buckets, sacks, drums, printed materials, and even woven goods. The lifting tubes can also lift raw materials and place them in position for emptying, weighing, and more. That is why they are increasingly used in food, pharmaceutical, or chemical industries.

The tube lifters are also used in different assembly processes where items are regularly lifted and placed in appropriate positions.

These devices are easy to use and install, as mentioned earlier. The device eliminates the need for manipulators or hoist systems. It has made it a lot easier to lift and attach loads. As soon as the vacuum pad is placed on the load, the airflow is blocked immediately, which increases the level of vacuum on the load. The device usually has a hand valve that helps to control the height and speed of air. Also, the valve is opened fully as soon as the load is released.

Features of the Tube Lifters

Here are some key features of tube lifting systems:

- Easy to Maneuver: The device was manufactured to make things a lot easier for you than complicated issues. Therefore, it must, more than anything, be easy to maneuver. That will also help in the easy and smooth movement of loads, so the device is used.

- Simple to Operate: As mentioned earlier. The tube lifters need to be as simple to operate as possible. This also applies to every other lifting and material handling tool.

- Corrosion Resistant: To ensure that the lifting system can stand the test of time, it is designed by using tools that can withstand corrosion. For example, in some tube lifting systems, the external surfaces are made from a combination of anodized aluminum, nylon components, stainless steel, and epoxy-coated metal. Interestingly, all of these materials are approved by the FDA.

- Vacuum Gauge: Tube lifting systems are also equipped with vacuum gauges, allowing for effective control of vacuum when lifting load. It will also enable the operator to secure the load firmly and prevent it from falling off.

- Multi-function lift control: These devices are designed to be versatile, which is why they have multiple features, all of which allow for lift control. They usually have adjustment knobs, a control handle, a nylon valve seat, and other elements that enhance the device's control.

- Check Valve: This is also a safety feature, especially for power loss. When using the device and a power outage or failure, you wouldn't want the device to release your item without caution. The check valve feature is designed to help secure the load in place even when there is a power failure. The loaded item will be placed on the ground quickly to ensure that it does not get damaged in the process.

- There are so many other cool features of the tube lifters. All these features work together for increased efficiency, productivity, and safety.

Tube lifters are suitable for different lifting operations because they are practical, precise, and safe for the movement of different types of objects. You can use them to grip additional items, including boxes, bins, cartons, domestic appliances, metal sheets, mirrors, and many more.