There are so many varieties of suction lifters, and they vary mainly in the size, design, and shape of their suction cups. When glass suction lifters are designed, there are so many factors that are put into consideration. First, the size, type, and weight of the material to be handled are considered, alongside the device's speed and precision. The next consideration is the type and size of the vacuum generator to be used, the pressure the system operates with, and other components like hoses, connectors, and valves.

No matter what is considered during the design, the device must safely and firmly hold the load it carries and resist other acceleration forces and gravity. The device must be able to reduce air consumption and prevent the load from getting damaged or ruined. Also, the device itself must be able to resist abrasion, fatigue and withstand contaminants and dirt. It must also stand extreme temperature conditions so that it can last for a very long time. The most important of them all is that the device should require very little maintenance.

Selection Criteria

There are so many things that are involved in the process of selecting a glass suction lifter. Different engineers use other criteria to choose a glass suction lifter. It usually depends on the cycle rates, aggressive surroundings, operating conditions, expected life, temperature conditions, and other environmental factors. These different conditions are considered because they all influence the performance of the suction cups, thereby determining how well the glass suction lifter will perform.

Since the suction pad plays a crucial role in these devices, another thing to consider is the material used in making the suction cups. Viewing the material used in making the suction pad is what determines the time of item it will be able to lift. For example, some materials are better suited for rough surfaces, while others are ideal for oily or smooth surfaces.

This is an essential consideration because glass is a smooth item that requires extra care and attention. When the wrong suction pad is used, it won't firmly hold on to the glass's surface, which can only cause further harm and damage.

Other Criteria for Selection

There are so many other things to consider when selecting a glass suction lifter. The most important thing is to ensure safety and increased productivity. Here are other factors that are considered in addition to those mentioned above:

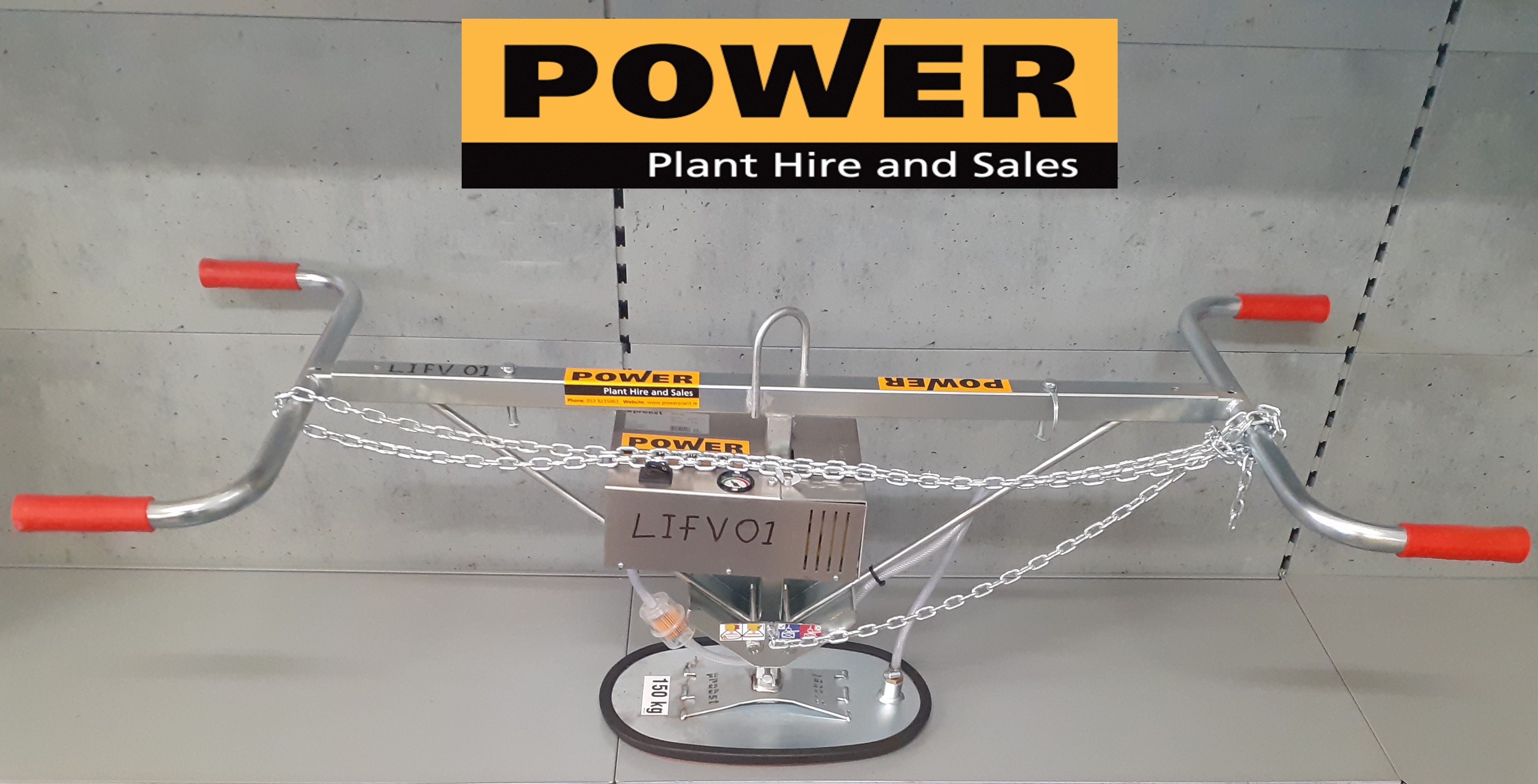

- Holding forces: This is also an important thing considered when selecting a glass suction lifter. The factors that determine the holding force include the shape and size of the suction pad and the rigidity, and the surface finish. All these play a crucial role in determining the efficiency of the suction lifter.

- Suction pad diameter: This is equally a crucial factor considered when selecting a glass suction lifter. The suction pad diameter plays a vital role in determining the holding force of the device.

- Suction capacity: This is depended on the vacuum capacity of the suction cup. However, it also influences the performance of the glass suction lifter and should not be ignored.

There are so many other factors that should be considered when selecting a glass suction lifter to hire. The importance of putting these factors into consideration is that manufacturers have designed all the available glass suction lifters concerning these factors, implying that they are better suited to serve different purposes. Therefore, when hiring a glass suction device, you need to ensure that the device can handle glass surfaces best.

Reasons for Hiring a Glass Suction Lifter

There need for workplace safety cannot be overemphasized, especially in terms of protecting workers and the items that are being lifted. Glass is one of the most fragile materials that require extreme care and caution when handling. Only the right tools should be used to manage glass or move glass from one place to the other, and the best tool for this purpose is the glass suction lifter.

Here are the main reasons to hire a glass suction lifter:

• For Safety Reasons: When glass breaks, it can easily cut through the skin. Firstly, you wouldn't want the material you are handling to damage. Secondly, you wouldn't want to get injured by the material you are running. That is why you need the glass suction lifter to increase safety from all angles.

• To Increase Productivity: Without the right tool, work processes will be slow and less productive. You need a glass suction lifter if you want to improve productivity.

Conclusion

Glass suction lifters are available in different forms for hire, and there are so many options for you to choose from. However, the most vital thing to ensure is that you follow all the considerations mentioned above before deciding.